SMART DESIGN of Commercial Vehicle

Using Tailor Welded Blanks

Tailor Welded Blanks are made from individual sheets of steel or aluminum of different thickness and strength which are joined together by laser or friction stir welding. This manufacturing process allows for optimized design using tailor welded solutions and thicknesses for various parts in CAB structures, variable thickness cross members and frame rails (chassis) resulting in:

- Cost Reduction

By using expensive materials only where necessary, parts in CAB and chassis can be produced at a reduced cost.Use of Variable strength and thickness TWB material in frame rails, cross members and CAB design can lead to scrap reduction and part consolidation resulting in significant cost saving.

- Light Weighting and Improved Payload

Through use of Tailor Welded Blanks (TWB) in CAB and chassis, weight reduction is realized (200+ kg weight reduction potential/vehicle).Light weighting using TWB smart solutions would allow for improved payload and freight efficiency and economic gain.

This would offset the new parasitic weight as well.

- Improved Performance

The use of higher strength and/or thickness material in highly loaded areas results in CAB and chassis improved NVH performance and structural integrity.

- Sustainability

The implementation of TWB leading to light weighting and reduction in CO2 emissions to meet current and future regulations.The weight reduction and smart design using TWB would facilitate medium and heavy-duty truck electrification resulting in longer driving range/charge.

-

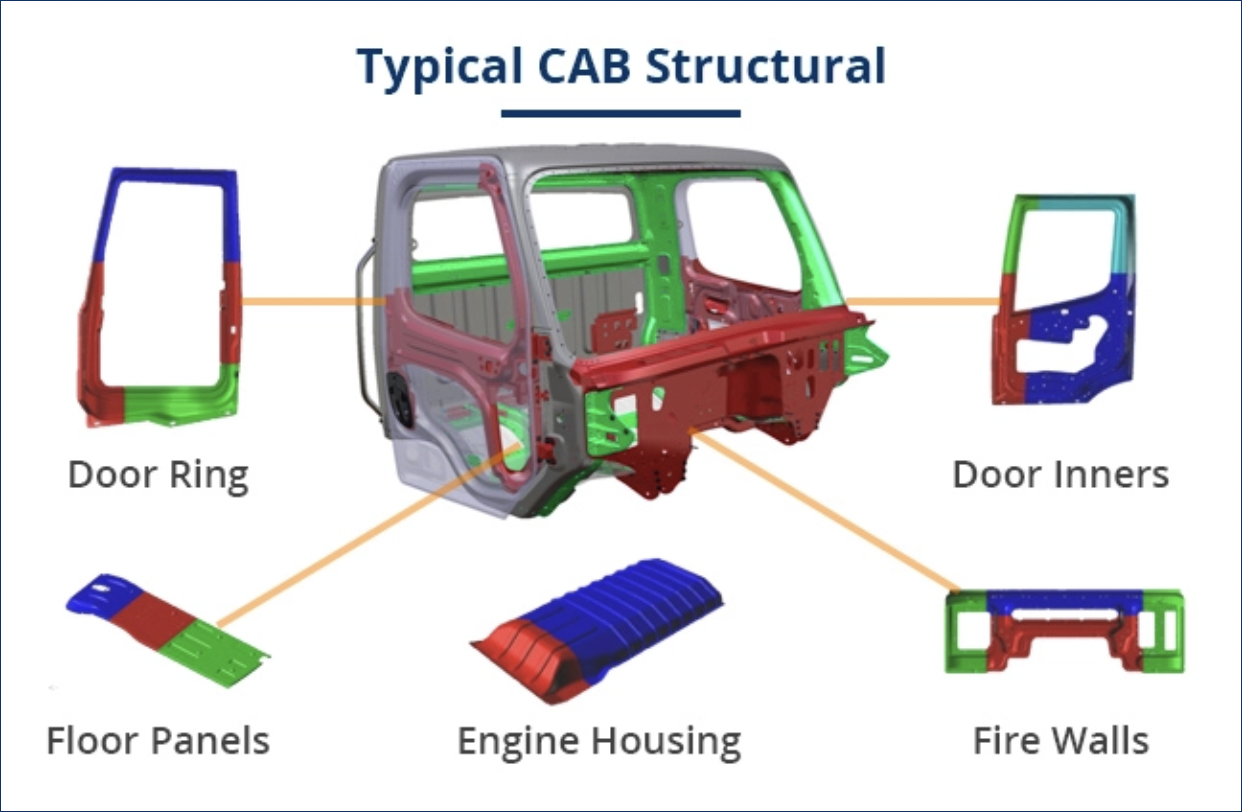

CAB and Closure Solutions

Variable thickness CAB parts offer major potential weight saving and cost reduction

-

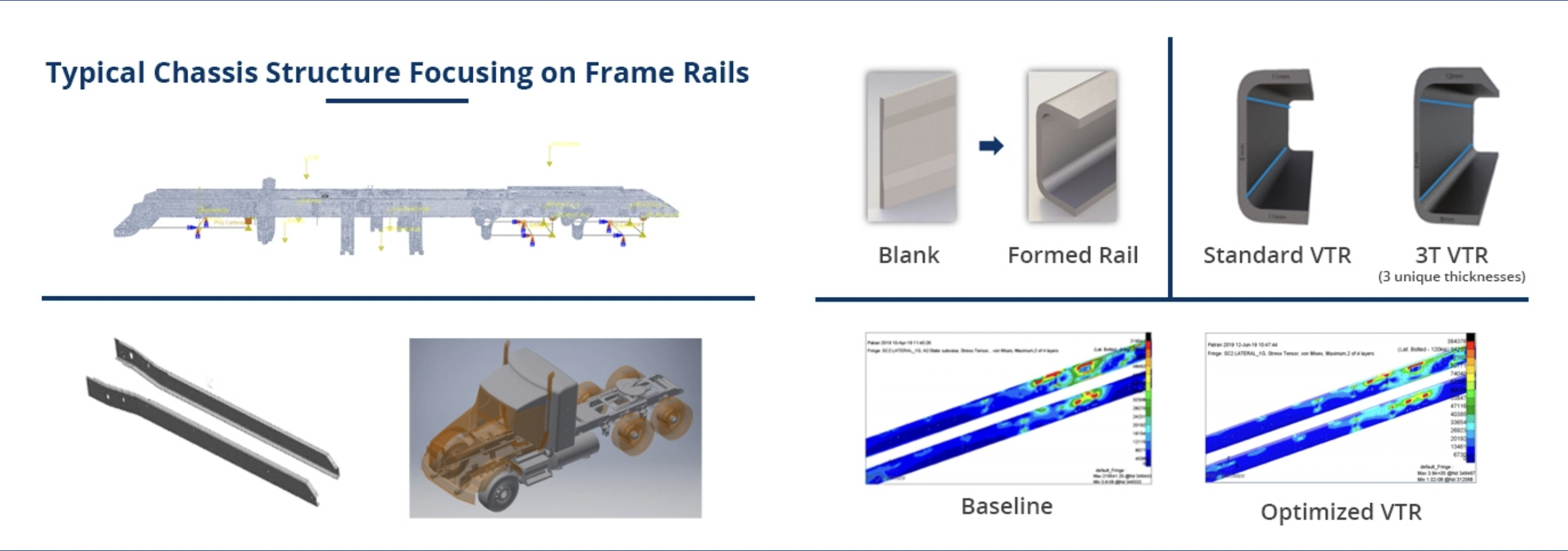

Chassis Variable Thickness

Frame Rails

VTR offers the largest weight savings potential for the commercial

truck industry while maintaining a steel structure